View our past projects! National Material Handling proudly serves as your US warehouse solutions and racking company.

Project #1

Customer

A transmission core refurbishing company

Challenge

The company faced significant inefficiencies and safety concerns due to a lack of structured storage in their 20,000 sf warehouse. Used automotive transmissions were unloaded from flatbed trucks and sorted into gaylords, which were then placed randomly throughout the warehouse floor.

This disorganized layout offered no formal aisleways, severely limiting the use of vertical space and making it difficult for forklift operators and material handlers to access the correct units efficiently.

The scattered placement of heavy-duty gaylords not only led to excessive and unnecessary touches but also introduced serious pinch point and trip hazards. The absence of or dedicated storage lanes compromised both productivity and safety.

Solution

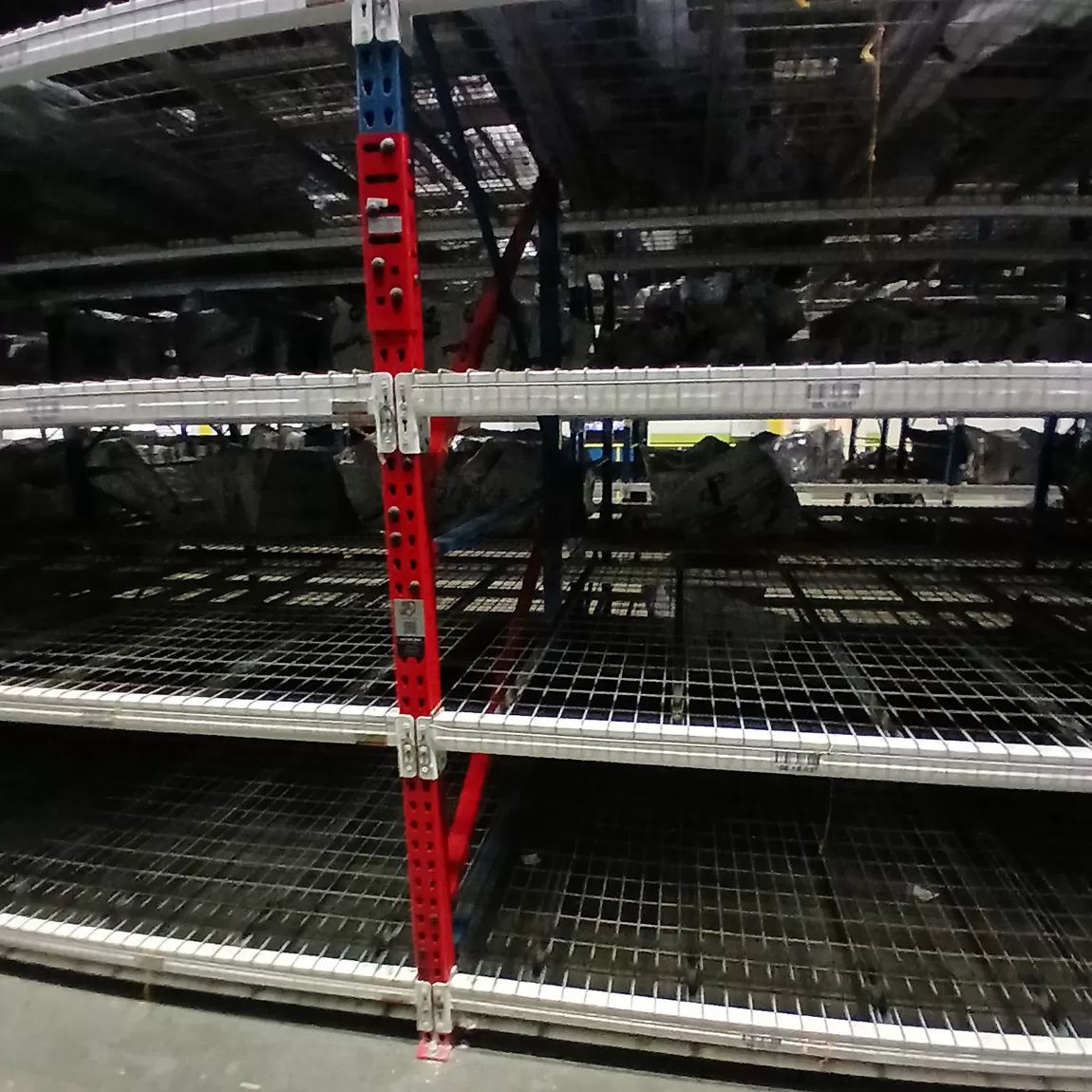

National Material Handling implemented a high-density warehouse racking solution using repurposed industrial pallet racks from a previous facility decommission. These heavy-duty steel pallet racks were designed to support the extreme weight of fully loaded gaylords, and the 28-foot-high racking enabled the customer to achieve four tiers of vertical storage, including the floor level.

To maximize operational efficiency and safety, our team designed and installed a structured layout with clearly defined warehouse aisleways, facilitating smooth navigation for both personnel and powered industrial trucks.

This optimized racking system not only enabled safer and faster picking and storing of transmission cores but also:

- Increased warehouse storage capacity by 33%

- Improved cubic space utilization

- Reduced labor time and unnecessary handling

- Minimized forklift congestion and safety risks

By strategically incorporating vertical pallet racking and streamlined aisle planning, the customer transformed their space from a cluttered floor-load operation into a clean, efficient, and scalable industrial storage system.

Before

After

Project #2

Customer

An automotive lighting systems manufacturer

Challenge

The customer relied on rolling racks to store materials, which significantly restricted storage capacity to only what could fit at ground level. With all materials confined to the warehouse floor, the facility quickly became congested, limiting workflow efficiency and increasing the potential for damage and disorganization.

As production demands grew, the lack of vertical utilization became a major obstacle to scaling operations and maintaining a clean, navigable workspace.

Solution

National Material Handling engineered a custom elevated structural steel mezzanine system to unlock the untapped vertical space in the facility. This high-strength platform was designed to support substantial material loads, creating a second tier of storage that immediately doubled the customer’s usable square footage.

To streamline the movement of materials between levels, two vertical reciprocating conveyors (VRCs) were integrated into the system. These industrial lifts allowed for safe and efficient transport of goods from the main floor to the mezzanine level without the need for forklifts or manual handling on stairs.

The final platform was well-lit, organized, and designed for safety. This mezzanine storage solution not only expanded capacity but also improved material flow, enhanced safety, and boosted overall efficiency within the warehouse.

Project #3

Customer

A worldwide leader in the manufacturing and distribution of construction materials

Challenge

The customer had completed the layout and installation of pallet racking for their new warehouse when they encountered a compliance issue involving the storage of combustible materials. According to NFPA (National Fire Protection Association) codes, combustible materials must be isolated in a fully enclosed, secured area.

While the code references chain link fencing, this material is far from ideal in a warehouse setting—it lacks modularity, isn’t structurally sound at heights beyond 12 feet, and offers poor adaptability around existing building elements.

Since the pallet racking was already in place, the customer needed a code-compliant containment solution that could be implemented without dismantling their new storage system.

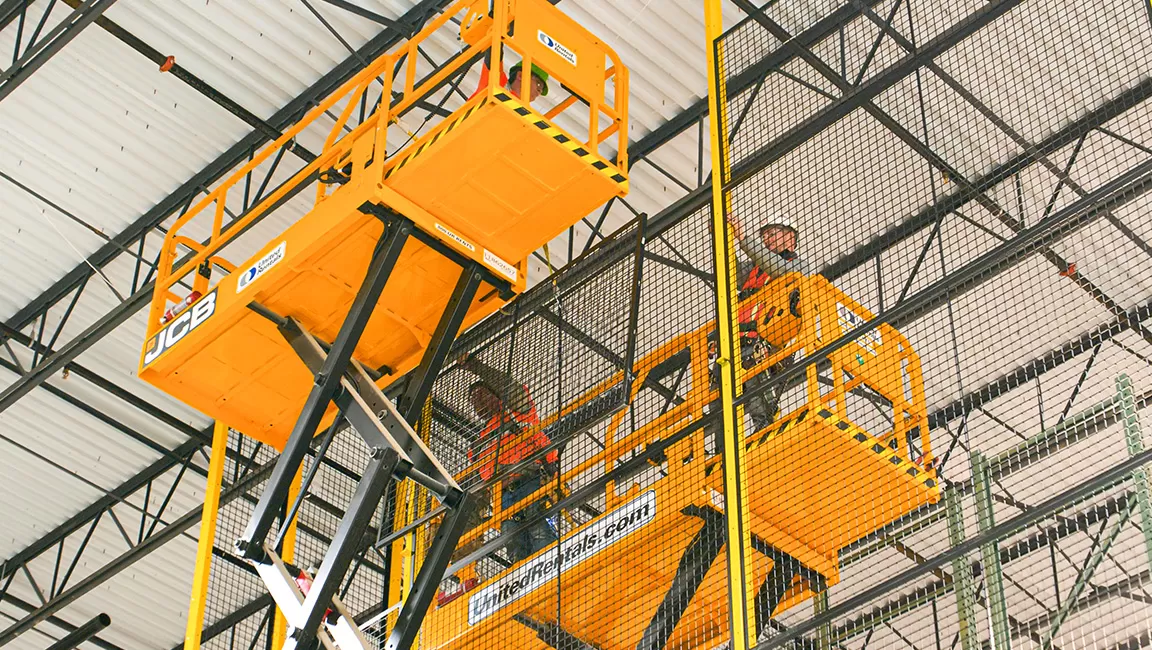

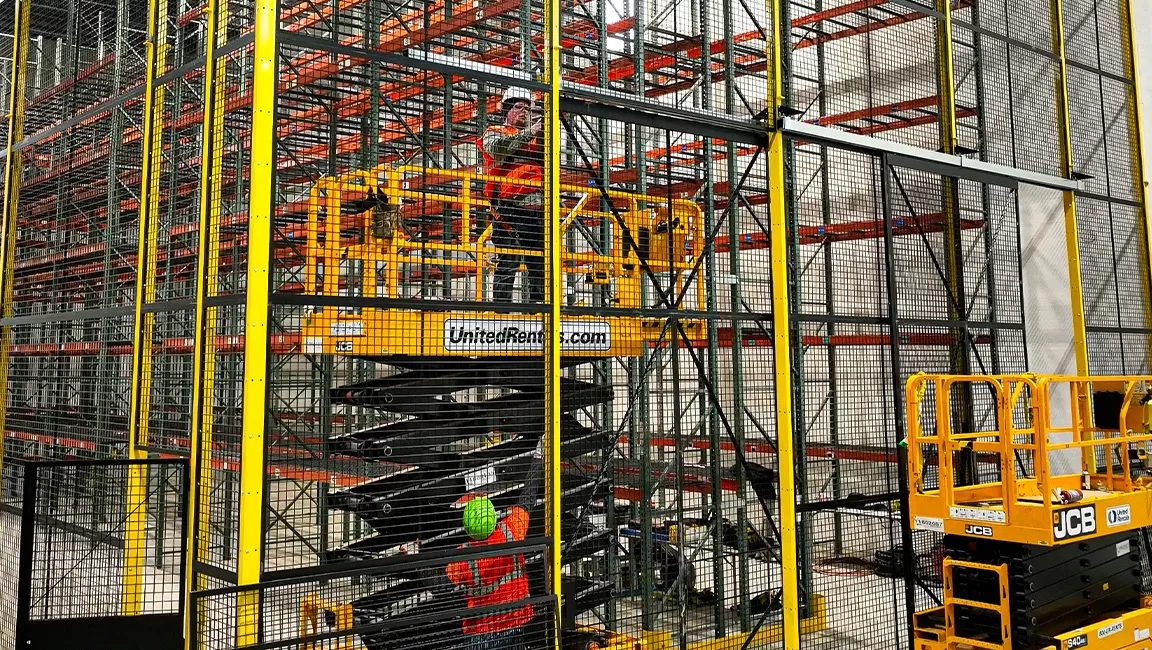

Solution

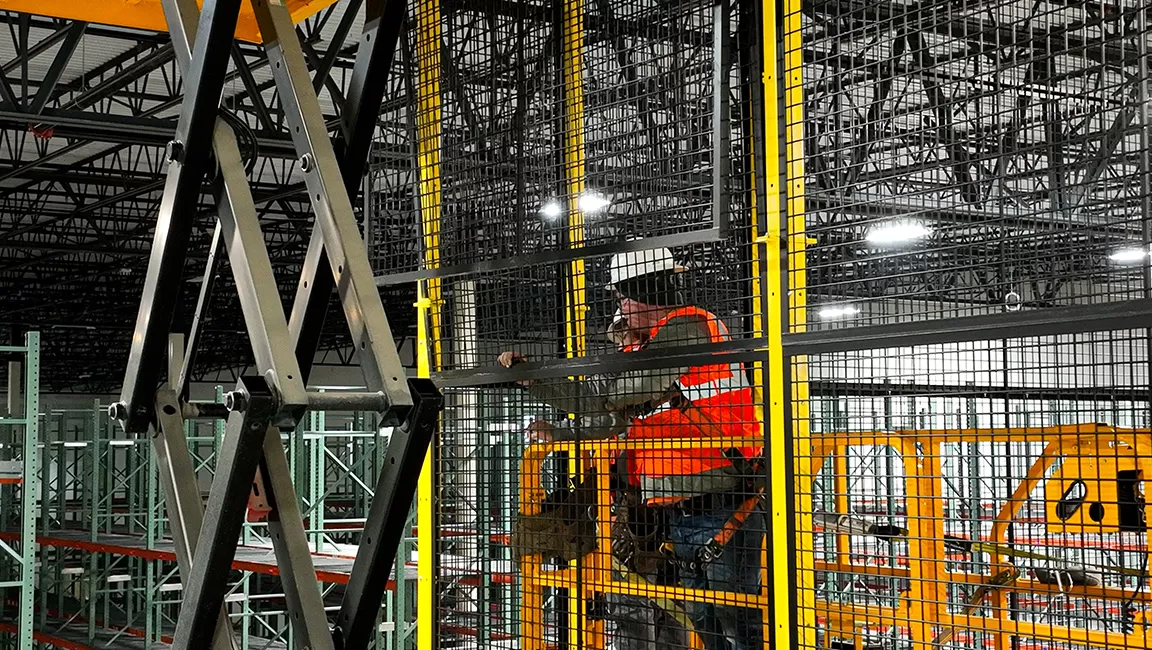

National Material Handling developed a customized containment system using 6a welded wire mesh partitions, a product that not only satisfies but exceeds NFPA code requirements. Unlike chain link, welded wire maintains structural integrity even when cut to fit around ceiling trusses, sprinkler pipes, or other warehouse obstructions, making it highly adaptable during field installation.

To ensure safety and operational efficiency, the system included two man doors with panic bars for emergency egress and two power-operated sliding gates for seamless forklift access. Additionally, we repositioned a row of pallet racking without dismantling, then re-chalked, anchored, and torque-tested the structure to maintain safety and stability.

This turnkey solution provided the customer with a safe, code-compliant, and easily serviceable containment area—all without compromising the integrity of their pre-installed racking or disrupting warehouse operations.

Before

After

Project #4

Customer

An aftermarket auto parts supplier

Problem

One of the customer’s pick trucks accidentally collided with a pallet rack upright, compromising the structural integrity of a critical storage bay. The impacted upright supported numerous beam levels, making a full replacement a labor-intensive and time-consuming task.

Dismantling and reinstalling the entire upright would have taken multiple hours, disrupted operations, and potentially delayed shipments from this busy distribution center.

Solution

National Material Handling responded quickly with a Centurion Rack Repair Kit, an engineered solution that allowed for a fast, durable repair without the need for drilling or extensive disassembly.

Using this specialized system, we were able to restore structural integrity and reattach the existing beams securely in less than an hour. This minimized downtime and allowed the customer to maintain full operational flow.

All materials required for the repair were in stock and pulled directly from our inventory, enabling us to mobilize and complete the project within 48 hours of receiving the order. Our repair team traveled to the site in Nashville, TN, and executed the fix just in time—prior to a scheduled safety audit.

The repaired upright now offers equal or improved durability compared to a full replacement, saving both time and cost for the customer while ensuring safety compliance.

Project #5

Customer

A corrugated packaging company

Challenge

The customer was facing a tight deadline—only three weeks to completely vacate their existing warehouse space. A major obstacle was the remaining pallet racking and related materials that still needed to be removed and properly managed before the move-out. These materials included a mix of stickered and non-stickered beams, uprights, and various accessories.

Failure to clear the facility and return it in acceptable condition could have led to lease penalties or delays in transitioning to their new space.

Solution

National Material Handling responded immediately with a turnkey warehouse decommissioning plan. Our team efficiently dismantled, sorted, and banded all racking components by type, including grouping stickered beams, non-stickered beams, and matching uprights for easy inventory management.

To help the customer recover value and avoid double-handling, we sold the racking materials directly from the site, eliminating the need for temporary storage or additional transport.

In addition to the equipment removal, we ensured that the warehouse floors were thoroughly swept and cleaned, meeting all terms and conditions specified in the customer’s lease agreement.

Despite the original three-week window, our team completed the entire project within just one week, allowing the customer ample time for final inspections and a smooth exit from the facility. This rapid and organized approach not only saved the customer time and money but also minimized stress during a critical relocation.

Project #6

Customer

A bio energy company

Challenge

The customer was racing against an end-of-year deadline to complete construction of two large anaerobic pre-treatment tanks, measuring 77 and 82 feet in diameter, to qualify for a tax abatement incentive. While the primary tank materials had been ordered and scheduled for delivery, a critical oversight was discovered late in the process: no safety railing or platforms had been ordered for the tanks.

This was a significant issue, especially because no field welding was permitted on the tanks, and shipping a pre-fabricated 82-foot diameter circular railing was logistically impossible.

Solution

National Material Handling responded swiftly with a custom-engineered, modular stainless steel handrail system designed to meet both the dimensional and regulatory requirements. Our engineering team created a segmented design that could be assembled on-site without welding, solving both the shipping and installation challenges.

Despite the compressed schedule, we completed the design, fabrication, and delivery in just six weeks. All weld procedures were documented and submitted for quality control approval by the customer prior to production. Leveraging our network of reliable steel suppliers, we sourced all necessary materials quickly.

Our team then cut, bent, welded, and packaged each component with care, including proper labeling and protective packaging to ensure easy and safe handling during installation.

Thanks to this modular solution and efficient project execution, the customer received all components ahead of the deadline, allowing them to complete construction and secure the targeted tax benefits.

Let’s Build Something Game-Changing

Ready to streamline your warehouse operations and eliminate the headache of managing multiple vendors? National Material Handling delivers comprehensive warehouse solutions that make your job easier and your facility stronger. Request your quote today and let’s get to work. Call our US racking and warehouse solutions company at (317) 886-0660 or fill out our online contact form.