Today’s warehouses are becoming smarter—and safer—thanks to cutting-edge technology. For a US racking and warehouse solutions company like National Material Handling, smart sensors are transforming how racking systems are monitored, maintained, and repaired. These sensor-based innovations are reducing downtime, improving safety, and giving warehouse operators real-time visibility into the health of their storage infrastructure.

Traditional Inspections: Limited and Reactive

Historically, warehouse racking inspections have been manual and periodic. These inspections often rely on visual assessments conducted by facility staff or third-party inspectors. While helpful, this approach has limitations: issues can go unnoticed between inspections, and any damage that isn’t immediately visible may lead to structural failure, inventory loss, or safety risks.

Most importantly, these inspections are reactive—meaning a problem is only addressed after it has already occurred.

Smart Sensors: A Proactive Approach

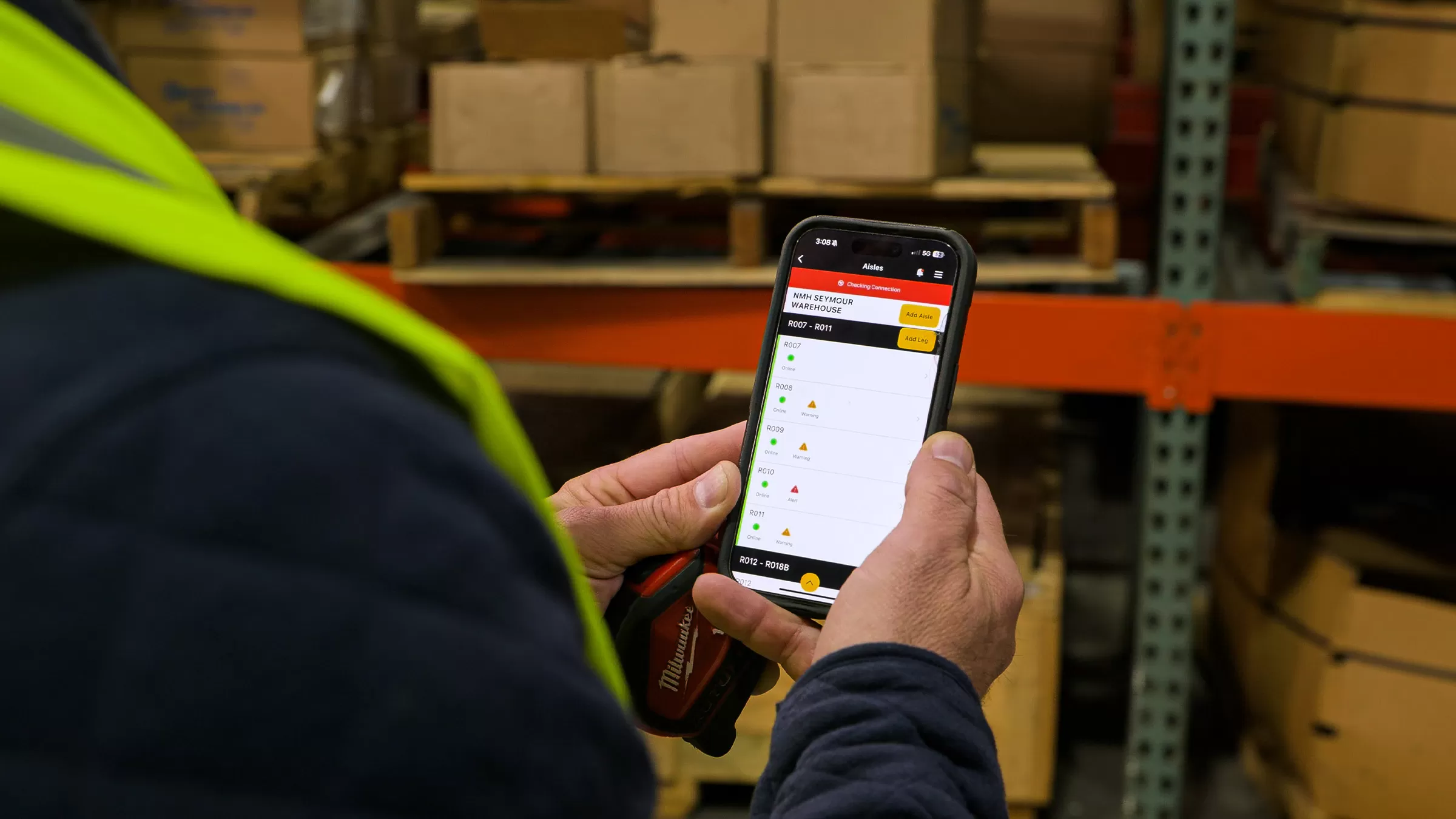

National Material Handling has introduced a sensor-based racking system that completely changes this dynamic. With smart sensors installed on the racking structure, customers receive real-time alerts when potential issues arise—whether it’s a bent beam, impact damage, or load imbalance. These alerts allow for instant action, ensuring that repairs or adjustments are made before problems escalate.

Instead of relying on scheduled inspections or visual checks, warehouse operators now have access to continuous monitoring. These sensors measure key indicators such as vibration, tilt, force impact, and more. The system can even prioritize alerts based on severity, making it easier for maintenance teams to focus on the most urgent concerns first.

Benefits Beyond Safety

While safety is a top priority, the benefits of smart sensor integration go beyond just protecting workers and inventory. Real-time monitoring helps minimize operational disruptions. By detecting minor issues early, warehouses can avoid emergency shutdowns or costly repairs. This increases overall uptime and allows businesses to plan maintenance more strategically—during off-hours or less busy periods.

Moreover, these systems provide valuable data over time. Facility managers can track trends, identify high-risk zones, and evaluate the effectiveness of training or layout changes. For growing operations or multi-site facilities, this level of insight is invaluable for maintaining consistent safety and performance standards across locations.

Smart Racking for the Future

The integration of smart sensors aligns with broader trends in and . As warehouse operations become more complex and high-volume, there’s growing demand for smarter infrastructure. Racking systems are no longer passive steel structures—they’re becoming intelligent frameworks that communicate with operators and support efficient, data-driven decision-making.

National Material Handling is at the forefront of this transformation, delivering innovative warehouse solutions that prioritize both safety and performance. Their smart sensor-enabled racking systems exemplify how technology can solve real-world challenges in logistics and material handling.

As warehouse operations evolve, the companies that invest in proactive, sensor-based monitoring will be best positioned for long-term success. By enabling real-time insights and faster response times, smart sensors are changing the game—and helping US racking and warehouse solutions companies like National Material Handling lead the way into a safer, smarter future.

Request a Quote for Sensor-Based Rack Systems

National Material Handling is proud to serve as your trusted US racking and warehouse solutions company. To request a quote for our sensor-based rack systems, please call (317) 886-0660. You may also fill out our online contact form and a member of our team will reach out to you soon to discuss the details of your next project.