Hydraulic Lift Tables

Hydraulic lift tables are a secure and precisely controlled platform that allows for the positioning, lifting, and manipulation of materials. Hydraulic lift tables alleviate physical strain on workers and enhance productivity by aiding in the positioning of products or equipment. Purposeful design ensures safe handling of load sizes of various weights and sizes and adjustable settings optimize ergonomic functionality.

Hydraulic Lift Tables

Hydraulic lift tables are a secure and precisely controlled platform that allows for the positioning, lifting, and manipulation of materials. Hydraulic lift tables alleviate physical strain on workers and enhance productivity by aiding in the positioning of products or equipment. Purposeful design ensures safe handling of load sizes of various weights and sizes and adjustable settings optimize ergonomic functionality.

Hydraulic Lift Table Types

-

- Scissor Lift Tables

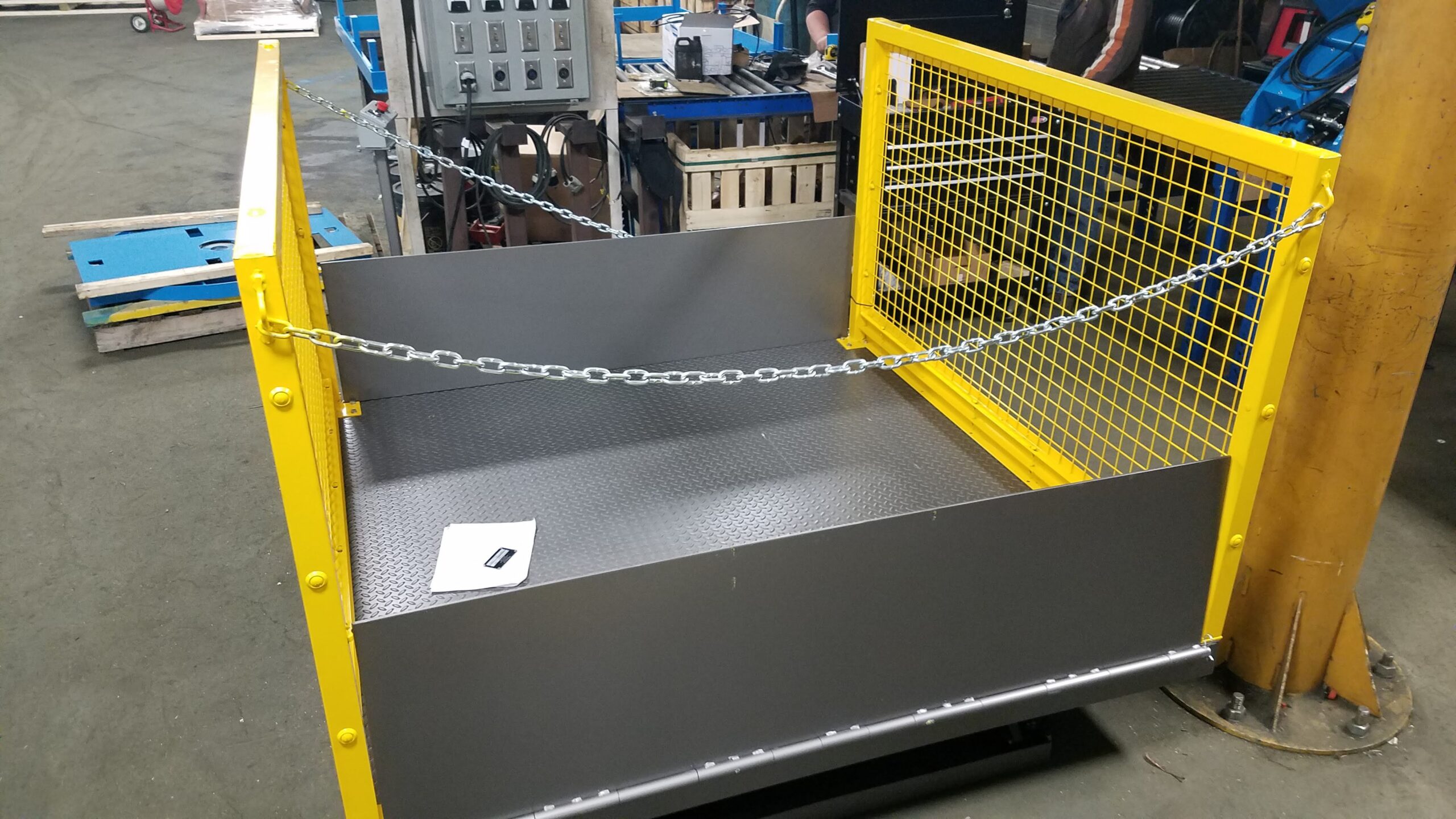

- Worker Platforms

- Conveyor Tops

- Stainless Steel

- Food Grade

- Turntables

- Dock Lifts

- Bascule Bridges

- Tilters

- Rotators

- Container Lift

- Portable Lift Tables

- Workbench Lift

- Cart Lift

- Stackers

- Coil Cars

- Parcel Unloader

- Mobile Lift Tables

- Ground Entry

- Low Profile

- Box Dumpers

Industries That Use Hydraulic Lift Tables

Manufacturing

Construction

Maintenance and Repair

Distribution

Warehousing

Medical

Automotive Manufacturing

Production

Laboratory

Retail

Government/Military

Dealership Parts Rooms

Entertainment

Fulfillment Centers

Pharmaceutical

Printing and Packaging

Food Processing

Energy and Utilities

Hydraulic Lift Table Features

-

- Lifting Capacity

- PLC Control Systems

- Electric-Hydraulic Power

- Mechanical/Screw-Type

- Safety Features

- Platform Size

- Fork Liftable

- Wheeled/Casters

- Power Travel

- Foot Pedals

- Tilt Functionality

- Dual Scissor or Multi-Stage Lifts

- Remote Control

- Fixed or Portable

- Load Rollers

- Optional Attachments

- Load Handling Attachments

- Flush-to-Floor/Pit Mounted

Hydraulic Lift Table Benefits

Precise Height Positioning

Lift tables and tilters allow for accurate and controlled height adjustments, necessary for products of various sizes and differences in employee height. When dealing with products of different dimensions, lift tables ensure the work surface aligns with the product for efficient handling and less damage.

Improved Ergonomics

By positioning materials at comfortable heights, lift tables promote better posture, reducing the risk of musculoskeletal injuries and strain, improving overall worker well-being.

Enhanced Productivity

Lift tables expedite tasks by providing quick and efficient vertical movement of materials, leading to faster load/unload cycles and improved workflow.

Flexible Load Handling

With a broad range of lifting capacities, lift tables accommodate a wide range of load sizes and weights, catering to diverse material handling needs.

Safety

Built-in safety features such as emergency stop buttons, toe guards, safety skirt and overload protection ensure the protection of both operators and the load.

Reduced Manual Handling

Lift tables eliminate or minimize the need for manual lifting, lowering the risk of injuries and strains associated with heavy lifting.

Optimized Space Utilization

Lift tables decrease the need for fork truck access, allowing for better servicing of manufacturing processes.

Precise Positioning

Lift tables enable accurate positioning of materials during assembly, maintenance, or processing tasks, reducing errors and rework.

Versatility

Lift tables can be used for a wide range of applications, from loading and unloading to assembly, maintenance, and packaging.

Increased Accessibility

Worker platforms make elevated areas more accessible for workers, enabling them to reach materials or perform tasks at different heights.

Customization

Lift tables can be customized with attachments, platforms, and accessories to suit specific tasks and applications.

Durability

Constructed with robust materials, lift tables are built to withstand the demands of industrial environments, allowing for continuous cycles, resulting in long service life.

Low Maintenance

Hydraulic lift tables generally require minimal maintenance, ensuring reliable operation and reducing downtime.

Cost Savings

Lift tables contribute to increased efficiency, reduced labor costs, and fewer workplace injuries, resulting in long-term cost savings. Insurance companies often provide reduced rates for installing ergonomic equipment.

Safe Handling of Fragile Items

Lift tables offer a controlled and precise method for handling delicate or fragile materials without causing damage.

Reduced Fatigue

By decreasing the need for manual lifting and repetitive bending, lift tables help reduce operator fatigue and maintain worker stamina.

Hydraulic Lift Table FAQs

Can I access a hydraulic lift table with a hand pallet truck?

Yes! Hydraulic Lift tables can be mounted in a pit that is flush-to-floor. Low-profile lifts with a ramp are also available.

Can a hydraulic lift table be utilized in different locations throughout a facility?

Hydraulic Lift tables can be provided with forklift pockets or with casters (either powered or non-powered) enabling it to be moved throughout a facility.

What types of top attachments are available for hydraulic lift tables?

Hydraulic lift tables have the following top attachment choices, conveyor top, ball transfer top, tilt top, turntable top, fixturing, and stainless steel.

Other Solutions

EMPLOYEE PRODUCTIVITY & WELL BEING

SPACE UTILIZATION & STORAGE

MATERIAL MOVEMENT

Site by tiny blue orange.